Medical HPL

What is Medical HPL (mHPL)?

mHPL is a form of SPC-HPL

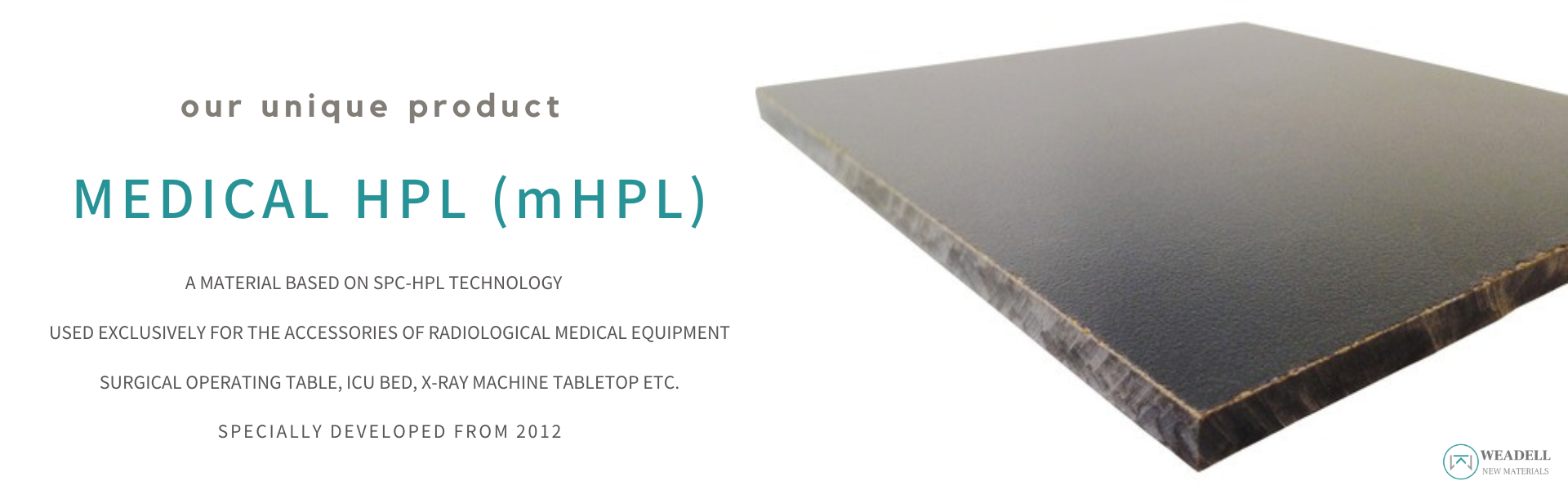

SPC, the acronym of the Solid Phenolics Compact, is a thermosetting material made from phenol, formaldehyde, and natural wood fiber as a cross-linking structure under high temperature and high pressure, usually produced as a high-pressure laminate (HPL). Weadell has over 10 years of experience in manufacturing SPC-HPL products, the Medical HPL is a variant of the SPC we developed for medical use.

mHPL is more suitable for medical use

Because SPCs are originally used as decorative materials, they can not meet very well the medical needs in such as environmental protection and radiology-related performance. So in 2012, by optimizing materials, changing auxiliary formula and improving technology, we successfully developed a kind of SPC product which is more suitable for medical use. To distinguish it from ordinary SPC, we named it Medical SPC-HPL, or mHPL for short.

PRODUCT APPLICATION

OR Tabletops

Made of mHPL Compact

Hospital/ICU Bed-Tops

Made of mHPL Compact

Veterinary Tabletops

Made of mHPL

DR/CT Tabletops

Made of mHPL Composite

Featured Performance

The mHPL has good x-ray transmission performance. It is a kind of material suitable for medical equipment and can be used to manufacture related equipment parts. The product has three major characteristics:

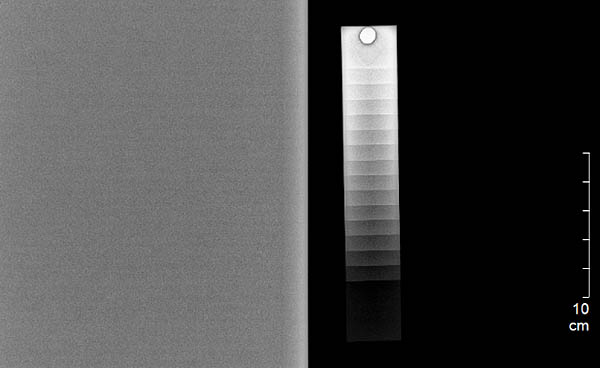

Radiolucent

The attenuation of mHPL is quite low. The experiments’ results show that the aluminum-equivalency of a 12mm thick mHPL composite plate is about 0.6 mmAL. X-ray machines using composite mHPL as tabletop can effectively shorten the exposure time, reduce the radiation dose and correspondingly avoid the excessive radiation exposure of patients. Because of this, melamine resin is very suitable for radiological medical equipment.

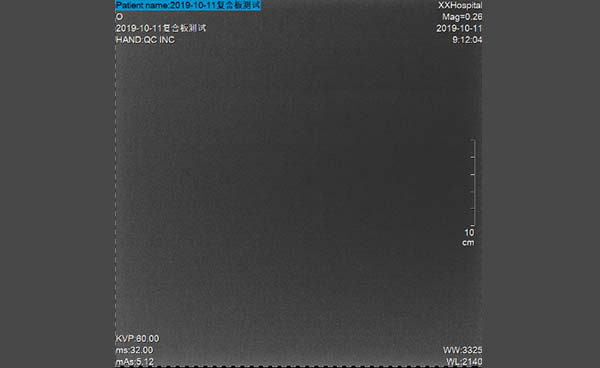

X-Ray Imaging Clean

A clean, undisturbed x-ray image is so important for clinical practice, that doctors can make accurate and efficient diagnoses. As the only medium other than the patient in the x-ray examination, the tabletop itself should be imaged as a background that is uniform, pure, of no visible impurities or spots. Our compact and composite mHPL products can do that. The special process and strict quality control ensure the quality of their clinical images.

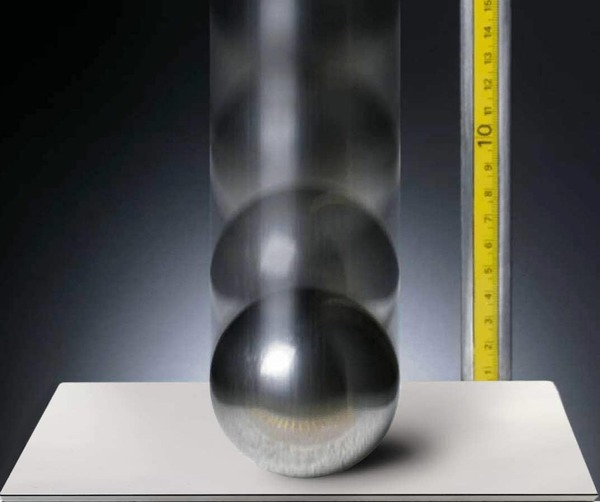

Excellent Mechanical Performance

The safety performance of medical equipment is clearly stipulated in all national and international standards. The mHPL has good mechanical properties and is an ideal material to be used as the supporting surface of medical equipment. For example, our composite mHPL DR tabletop, made of melamine resin and special rigid foam, is light, thin, and proved to be of high bearing strength.

Other Performance

Subcategory

Weadell mHPL Products are manufactured in a customized manner, including raw material production and processing according to drawings

More Data

|

NO. |

Examination |

Measure Units |

Test results |

|

|

2mm |

6mm |

|||

|

1 |

Tensile fracture strength |

Mpa |

40 |

104 |

|

2 |

Tensile strength at break |

% |

1 |

1 |

|

3 |

Flexural strength |

Mpa |

69 |

145 |

|

4 |

Cantilever beam notched impact strength |

J/m |

10 |

31.9 |

|

5 |

compression strength(10%) |

Mpa |

221 |

226 |

|

6 |

Rockwell hardness |

/ |

122 |

124.4 |

|

7 |

Bibulous rate(23℃, 24h) |

% |

0.45 |

0.46 |

|

8 |

Linear expansion coefficient (-30℃-30℃) |

℃-1 |

1.71×10-5 |

1.62×10-5 |

|

9 |

Aluminum equivalent |

mmAL |

<0.4 |

<1 |